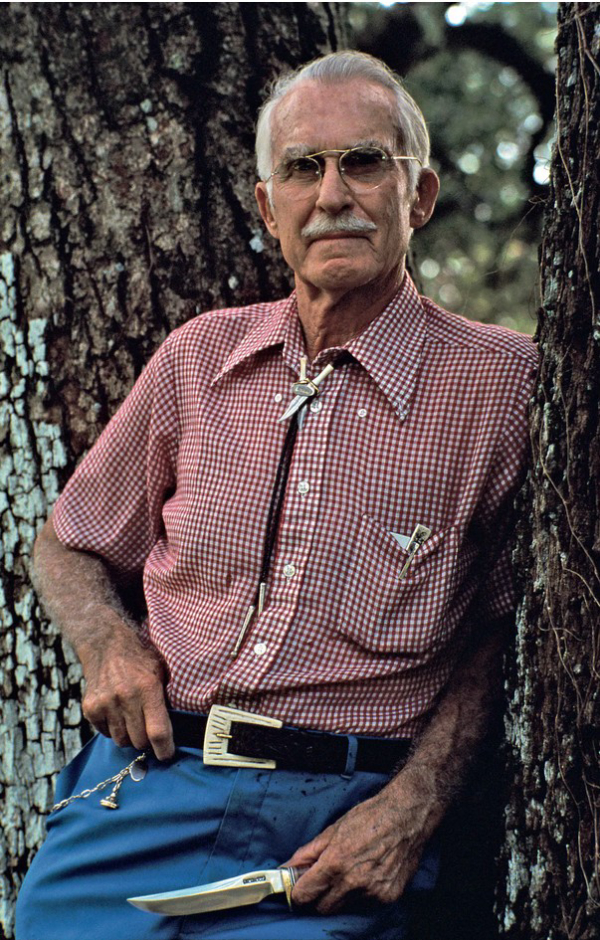

By dumb luck, I was assigned to do a story on Randall Knives when I was about 25 years old by what was then one of the most revered national outdoors magazines, Sports Afield. The magazine is sadly gone, but that tour through the Orlando factory of this venerable company opened my eyes to the art and science of maintaining edge tools the rest of my days.

The company was founded in 1937 by "Bo" Randall Jr. and continues to be a family-run business with 20 craftsmen producing about 8,000 high-dollar knives per year—their large Bowie now goes for over $800 (www.randallknives.com).

Bo was in his latter days when I visited, but he still came to the factory every day and paid particular attention to the guys who put the finished edge on those knives, one of whom told me this:

“You don’t sharpen a good blade—you straighten the edge.”

Which is really all you need to know about sharpening knives, if you take it to heart.

Once a knife is properly sharpened, which a skilled worker can do in a few passes on a grinding belt, all it takes to restore it to razor sharpness is a few light back strokes on a steel or even a rough leather strop.

For hunting knives, the original blade angle is likely to be something close to 25 degrees, and for fish/poultry knives, around 18-30 degrees.

The blade angle is measured where the two sharpened edges meet. For example, a 10-degree edge on one side and a 10-degree edge on another side, equals a 20-degree edge. Your shaving razor might be as fine as 7 degrees, but that’s not strong enough for cutting up fish or skinning deer.

But once the original grind is put in, all you need to worry about is that final edge, and it can be kept working sharp with a few strokes on a fine stone, a steel rod or even a leather strop. (If you have to use your knife to whittle tent pegs, on the other hand, you may have to do some serious work with aggressive sharpening stones to put it back in shipshape.)

In fact, pro fish cleaners, who spend eight hours a day cutting fish, sometimes sharpen their blades by simply stroking the edge on the back of another knife unless they’re really dull.

The secret of a sharp knife is to sharpen it right the first time, and then never let it get dull after that—after every few uses, a few light pulls across a fine stone or diamond-coat sharpening rod will return that edge to razor-like effectiveness.

Custom knives typically come out of the box hand sharpened and then stropped on leather or other flexible material to create the finest, smoothest edge consistent with the cutting jobs the blade is designed for—finer for fillet knives, heavier for hunting/skinning/boning knives.

There is also such a thing as “too sharp”. If you hone an edge down to excessively microscopic, it’s too weak to cut anything other than the obligatory sheet of paper.

If your knife does get dulled, it’s good to have a multi-grit sharpening stone, or for faster work, a diamond coated stone. You need one at least 6” long for effective work on multiple knives. The little diamond sharpening rods available on Amazon for $10 to $15 are good for touchups.

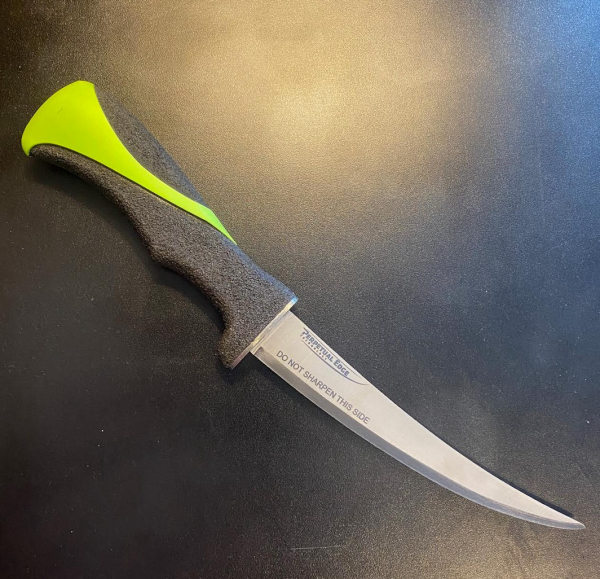

A “Beaver-Tooth” Knife

Relentless Knives, headquartered in Florida, has what seems to be a truly original approach to sharpness, building knives that combine a titanium blade with a laser cured carbide and crushed diamond "Power Strip"on one side, creating a differential hardness. The company says the harder Power Strip wears slower than the softer titanium, leaving a razor-sharp edge that literally sharpens itself as it cuts, sort of like the teeth of a beaver.

This sounds odd but it appears to work for users. Captain Dylan Hubbard, who runs multiple party boats out of Treasure Island on Florida’s Gulf Coast, says his teams have been using the knives for months and they rarely if ever need re-honing.

“We use these knives every day to clean a bunch of big, offshore reef fish and we just haven’t had to sharpen them at all,” says Hubbard. “They also haven’t shown any rust so far, which is pretty amazing on saltwater fish.”

The knives also have rubberized non-slip handles molded with stuff similar to that used in non-slip swimming pool decks, so you’re very unlikely to lose your grip.

Relentless offers five fishing knives from 6” to 10” long, and two hunting knives, a skinner and a drop-tip. They’re fairly pricey for fillet knives, at $150 to $160 each, but considering the features this may be a good investment for an angler who cleans a lot of fish.

Learn more at https://www.relentlessknivesusa.com.