Located in the sleepy town of Bridgeville, Pennsylvania, a mere 20 minutes from downtown Pittsburgh, Shaw Barrels is as unassuming as the town itself. Hidden by the veil of old industrial buildings, the casual passerby would have no inclination that behind the building’s walls lies one of the largest barrel makers in the United States.

For those of an older generation, the name E.R. Shaw might ring a bell. When Carl Behling, the 30-year-old CEO who took over after his father’s sudden passing, was asked, he changed the name so that potential customers would understand what they do—they make barrels. And they can produce them at an unprecedented rate without sacrificing quality.

After spending the day with them and learning about the barrel-making process, I have a newfound respect for what they do.

Who is Shaw Barrels?

Shaw Barrels started as a manufacturer of nuts and bolts for the railroad industry over century ago. As the U.S. shifted its attention to the battlefields of World War I, production focus shifted to wartime needs, leading the company to focus on manufacturing small arms barrels. After the war, they established Small Arms Manufacturing, which became a leading supplier of OEM gun barrels.

Today, Shaw Barrels operates three plants that produce premium-grade gun barrels in various types and styles. While 85% of their business is OEM work, the remaining 15% is comprised of direct-to-consumer sales through their website. For online customers, they keep over 7,800 barrels in stock covering nearly every option you can think of for 10/22s, AR-15s, AR-10s, and even FN PS90s. And that doesn’t include the custom barrel options for your bolt-action needs. It’s truly impressive.

Barrel Making

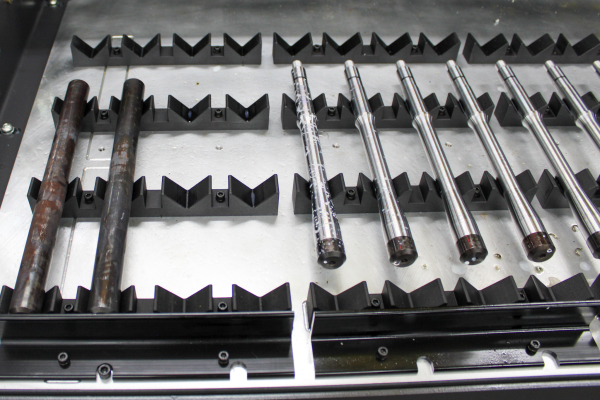

As mentioned above, Shaw Barrels encapsulates three separate buildings throughout Bridgeville. Each plant encompasses unique stages of the barrel-making process. Building One is responsible for receiving the raw steel, parting it to length, drilling the initial bore, reaming, button-rifling, and performing the heat stress relief in an industrial oven.

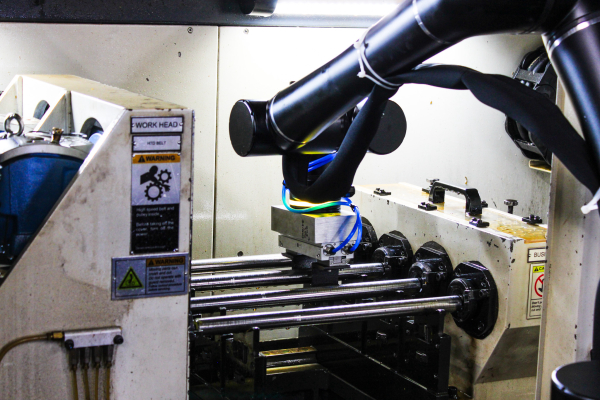

Watching the machining in action, a blend of pre-war nostalgia and cutting-edge robotics, Shaw adopts a modernized manufacturing approach that combines the best of the old and the new.

In Building Two, the barrels really take shape. Here, each barrel is turned on a lathe so that the outside diameter is concentric with the bore (with tolerances in the thousandths of an inch), and then hubs are threaded, and chambering (if required) occurs. It’s all done on modern CNC machines. For AR barrels, gas ports are drilled, and barrel extensions are torqued on.

From there, barrels go to Building Three. There they are contoured, fluted, and finished. Shaw will sandblast and blue in-house. Other finishes, including chrome lining and nitride finish, are done outside by partners. Shaw can also laser-etch barrels for their clients, allowing them to add their own unique markings. This is also where orders are packaged and shipped, with each one individually pulled and inspected before heading to its new home.

While Shaw can produce barrels quickly, they take pride in the quality of their products. To ensure top-notch barrels, they add extra steps throughout the process. This includes polishing tooling to reduce chatter and tool marks, as well as using slower spindle RPMs when reaming, for the same reasons. They also have an automated saw for parting, which increases speed without the need for additional operators. They can do this because of their investment in machinery.

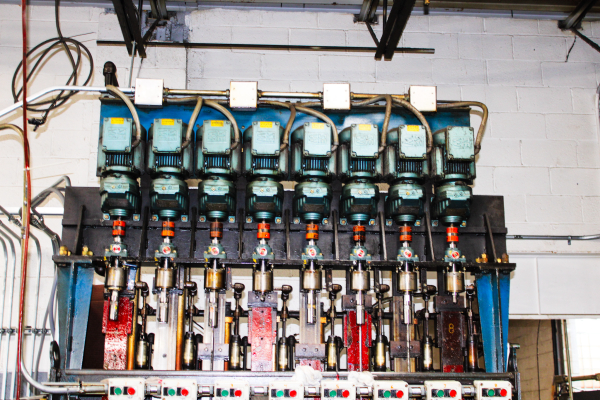

Shaw operates three eight-spindle boring machines, five button-rifling machines, ten deep-hole drills, and automation in key bottlenecks to boost efficiency. That’s really what Behling has focused on—making production more efficient to improve quality and output.

But that doesn’t mean they can’t do things the old-fashioned way. That’s where the Shaw Barrel’s custom shop comes in.

Shaw’a Custom Chop

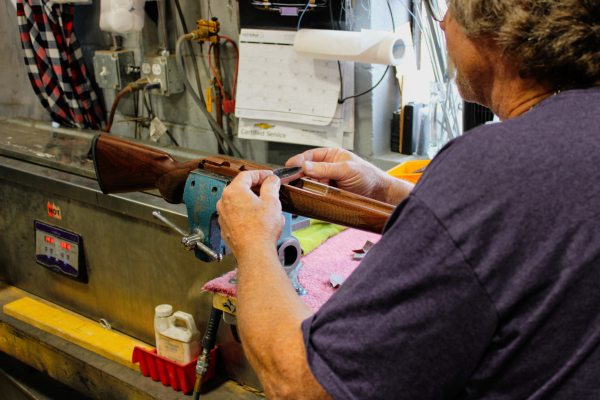

Stepping into the custom chop is like stepping back into a bygone era. There, craftsman meticulously pore over each project, ensuring that customer expectations are exceeded. This is also where Shaw’s own line of custom rifles, the Excursion, is built. While they keep a few “in-stock” Excursion rifles, each one can be made to order. And the options are endless.

A user can curate the rifle to precisely what they are looking for. Not only that, the custom shop operates as a custom gunsmithing service, where you can send in your rifles to be re-barreled, blueprinted, and more. And it doesn’t come as a surprise that Shaw has a top-flight custom shop—the Pittsburgh Gunsmith School is right down the road.

Zooming Out

Shaw Barrels is an impressive operation. They’ve been doing it for a long time, however, under Behling’s leadership, they’ve worked to build a new identity focused on quality and efficiency. The process they’ve developed over the last century shows that. There’s a reason why they’re one of the most trusted names in barrel-making. Be sure to check out Shaw Barrels for your next project. You will be impressed by the options, pricing, and quality.

— Cory Ross, Shooting News Weekly