|

RENO, NV –– Reno Cerakote, the Nation’s premiere high-volume Cerakote applicator, launched their new Supercell production line in Mid- March and has already seen the benefits of the increased daily throughput.

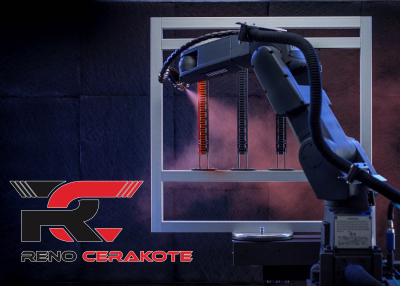

The Supercell is a manufacturing line that has different machinery set up in a circle to eliminate the process of pieces moving down an assembly line. Pieces are removed from the box at the sandblaster, etched per the Cerakote requirements and then placed directly on the coating rack. From there a robotic applicator precisely Cerakotes each of the pieces. The pieces are then moved from the Cerakote station just a few feet over to the oven to cure. This process allows fewer people to get more parts coated by reducing the amount of movement it allows them to travel quicker through the coating process.

Within a few months of the Supercells implementation Reno Cerakote has already seen an increase in daily product throughput. Prior to the supercell they had an average daily throughput of 1,000 items and now they are able to put out approximately 1,400 parts per day.

To see the Supercell in action, click HERE to watch the video.

Our Mission

To provide premiere coating application through the use of cutting-edge technology, with quality as our highest priority.

About Reno Cerakote.

Reno Cerakote was established in 2015. What started out as a single man operation has quickly grown into a full-scale production facility that possesses three robotic applicators and employees over forty people.We attribute our success to the excellent quality we provide our customers. At Reno Cerakote quality isn’t just a word, “Quality is Our Brand.” Our employees and top of the line technology are the reason we’re the Cerakote center of excellence.

Additional information is also available at www.Renocerakote.com

For the latest news from Reno Cerakote follow us on Facebook,Instagram, Twitter, Linkedin, and YouTube